Tradeasia International Pte. Ltd. always had a strong bond with basic industrial chemicals and its trading. We have a strong network with Asia Pacific, European Union and Middle East. We provide our customers not only quality product but also extended supply management services

Market

Our High-Quality Soda Ash Light business has reached many markets of soda ash in Africa, Asia, Europe, and America. We are experts in the soda ash market in many countries and have encountered more than a thousand companies worldwide.

Soda Ash Light

Soda Ash, or Washing Soda, is a versatile sodium salt of carbonic acid used in glass, chemical, paper, and detergent industries. It naturally occurs as Natron, Sodium Carbonate Heptahydrate, and Thermonatrite.

Applications

Glass Manufacture

Image Accordion Content Goes Here! Click edit button to change this text.

Textile and Leather

To enhance the pH (alkalinity) of the reaction, soda ash Light is used in dyeing cotton and other cellulose fibres such as linen, rayon, tencel, or hemp. The optimal pH varies depending on the fiber and dye color. Soda ash alters the pH of the fibre-reactive dye and the cellulose fibre, causing the dye to react with the fibre and form a permanent bond with it.

Soap and Detergent

Soda Ash enhances detergent performance in hard water, removes alcohol and grease stains, and is key in cleaning products. Used in soaps, scouring powders, and detergents, it acts as a builder, surfactant carrier, and pH adjuster.

Chemical Raw Materials

Soda Ash: A Key Source of Sodium Ions for Sodium Phosphates, Silicates, Chrome Compounds, and Photographic Chemicals. Essential for Making Sodium Bicarbonate (Baking Soda) used in Beverages, Coatings, Detergents, Food, Dialysis, and Personal Care Products.

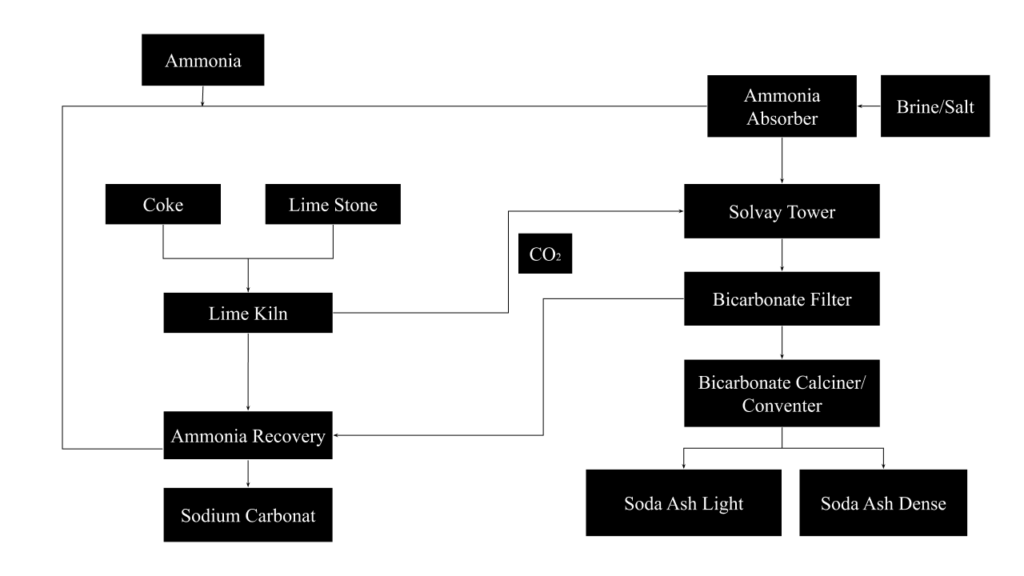

Manufacturing Process

The main reaction of the manufacturing process is the reaction of salt, ammonia and carbon dioxide to form a dense ash and intermediate ammonium chloride. Dense ash is separated by sedimentation. Slaked lime is used to degrade ammonium chloride from the mother liquor. The recovered ammonia is recycled, and inventory is only needed to compensate for the loss. The dense ash is heated in a kiln, and soda ash is generated from carbon dioxide and recycled as in reaction.